TeleCentric Centric vice

With an optimum interference contour for the 5-axis machining

Why the TeleCentric?

- Maximum accessibility

- Safe and reliable clamping

high precision

low susceptibility to vibrations - short changeover times

quick change jaws

for zero point clamping systems - easy operability

simple jaw change

light weight - For small and medium-sized machine tables

optimum table size: 280-400 mm

Note: Click the button to play the video. Data will be transmitted to the respective third-party provider.

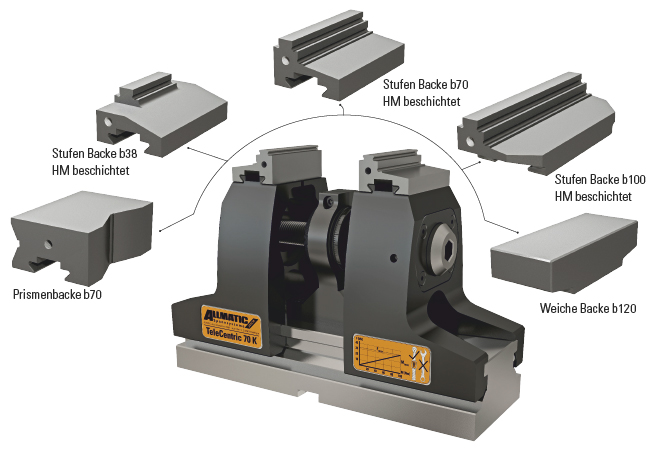

Conventional clamping

For small and medium-sized machine tables

In conventional clamping, parallel, rough-worked or flat workpieces and materials are clamped. Generally, the conventional method is used for the second clamping procedure or for workpieces with a parallel error of up to 0.05 mm.

The optimum table size is 280-400 mm.

This image shows a versatile jaw assortment, which is suitable for rough-worked workpieces.

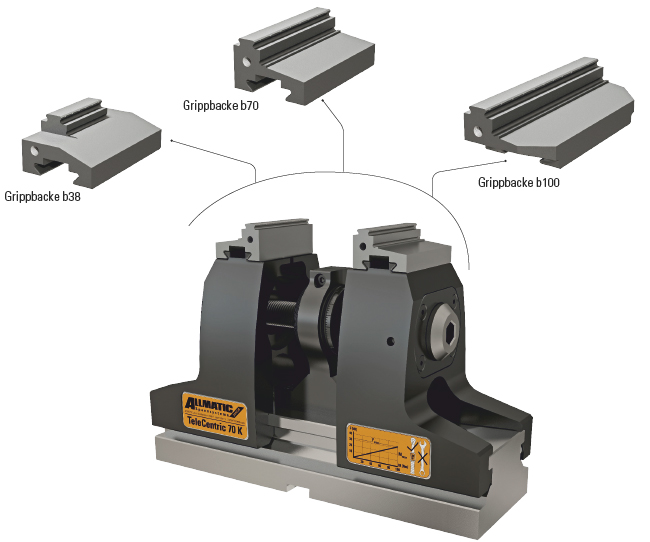

TeleCentric with GRIPP quick change jaw system

5-axis vice with GRIPP

For GRIPP Clamping, unmachined, non-parallel parts or raw materials are used.

Pre-roughened workpieces:

– Suitable for material strength of up to 1000 N/mm²

Raw materials:

– Suitable for material strength of up to 550 N/mm²

– Error in parallelism up to 0.3 mm

With the jaw systems, you can clamp parallel workpieces safely and quickly. Stamping and clamping happens in one process.

Expansion of the portfolio

ZERO JAW

With the TeleCentric 70 K you can now clamp parallel, pre-machined workpieces with a clamping range of 0 to 69 mm. The dowel pins provide an exact vertical positioning of the workpiece and can be set at heights 176 mm and 191 mm.

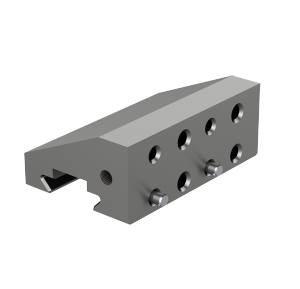

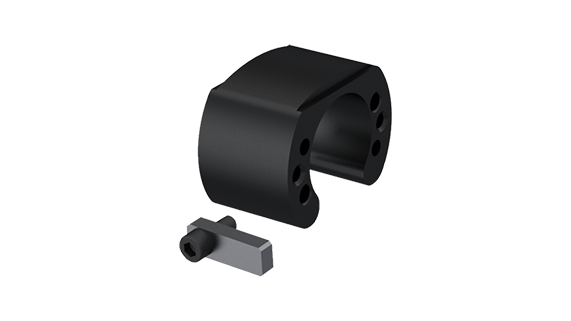

Support jaw b120

For clamping raw parts, irregular and round workpieces. For the mounting of various gripper studs.

Clamping range adapter

The adapter is suitable for the TeleCentric 70M and allows you to achieve a clamping range from as little as 9mm (with the zero jaw even 0mm).

Examples of use

The functions of TeleCentric 5-axis vice

Note: Click the button to play the video. Data will be transmitted to the respective third-party provider.

Customer Examples

TeleCentric on Tour

Note: Click the button to play the video. Data will be transmitted to the respective third-party provider.

TeleCentric 5-axis vice for conventional and GRIPP clamping

Shorter changeover times and greater flexibility

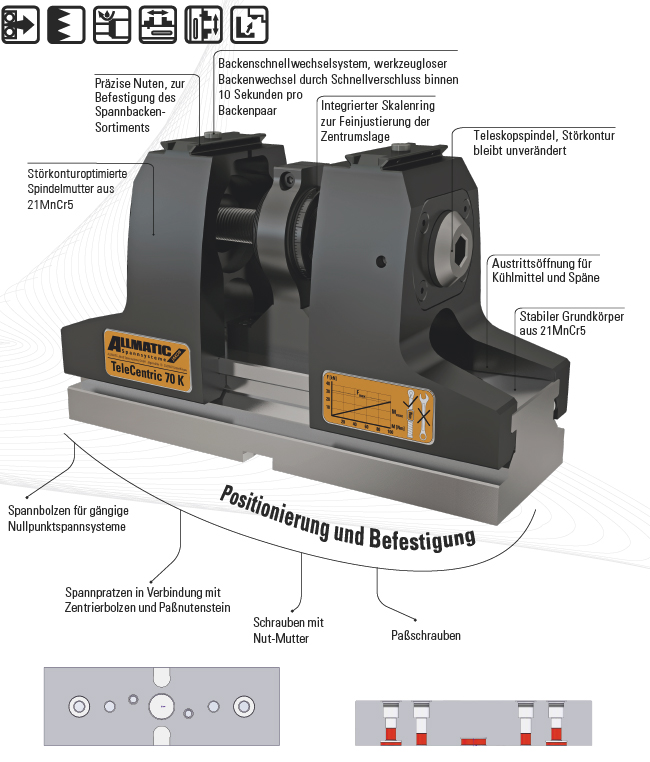

The ALLMATIC TeleCentric is the centric vice for 5-axis machining.

The interference contour remains the same, independent of the clamping width, thanks to the centric construction type of the telescopic spindle.

This innovation guarantees an optimum interference contour and the best possible accessibility of the tool due to the way in which the inner and outer threaded spindle parts move towards each other. This allows for the 5-axis machining. Thanks to the centric function, no zero point is displaced; hence the material allowance can be divided in half as a result of the symmetric distribution.

In series, the 5-axis vice is fitted with a quick change jaw system, which in turn makes for short changeover times and greater flexibility.

For example, even the sixth side can be machined by quickly inserting of another jaw. The toolless jaw change does not even take 10 seconds per jaw pair.

Weighing in at a maximum of 19.5 kg (without the jaw), the TeleCentric is deemed a lightweight in the world of clamping fixtures, all the while being very versatile. This way, it contributes to the optimization of the production process and is a very user-friendly fellow in any machining company.

*Satisfaction guaranteed: Sale or return within 30 days upon receipt of the goods and payment in full, if the vice was used properly and does not show any signs of damage. The TeleCentric must have been purchased from ALLMATIC Jakob Spannsysteme GmbH.

TeleCentric 70 K

- Weight (without jaws): 17.5 kg

- Clamping force: 30 kN at 45 Nm linear

- Clamping range for conventional clamping: 9-135 mm (with zero jaw 0-135mm)

- Clamping range for GRIPP clamping: 9-134 mm (with support jwas 0-134mm)

- Length: 286 mm

TeleCentric 70 M

- Weight (without jaws): 19.5 kg

- Clamping force: 30 kN at 45 Nm linear

- Jaws reversible: 49 mm – max. 207 mm clamping widths with one pair of jaws (with clamping range adapter from as little as 9 mm; with zero jaw even from 0 mm)

- Clamping range for GRIPP clamping: 42-199 mm

- Length: 351 mm