Your entry into automation

The new clamping aid “WorkBuddy”

WorkBuddy – Your assistance in mechanical clamping

The WorkBuddy has been successfully used in our own production for mechanical workpiece clamping for quite some time.

+ For ergonomic, joint-friendly operation of tombstones

+ Reduction of operating errors results in safer processes

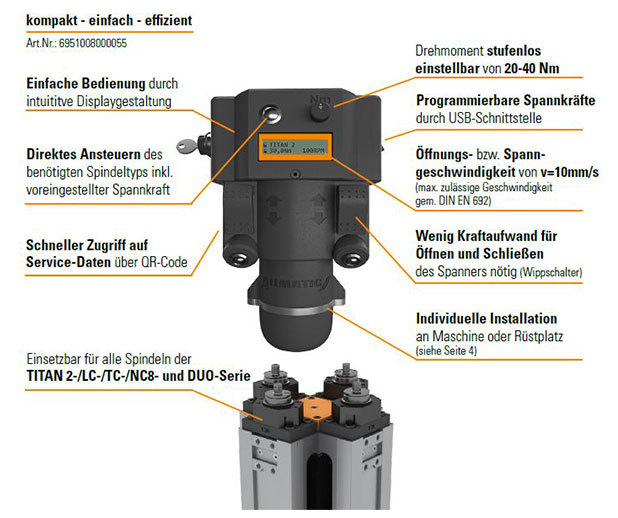

+ Quick opening and clamping process (v = 10mm/s)

+ Individual installation at the machine or set-up station

A overview of the product features

The operation protects back and shoulder area

CEO Herbert Mayr

„We use the WorkBuddy even in our own production – loading a total

of 56 different tombstones for two milling machining centers out of

a pallet shelf at the set-up station. That way the WorkBuddy clamps

more than 20,000 parts per year.

At the moment we clamp up to 40 different workpieces with different

clamping forces. But this is far from the end. This is why the WorkBuddy

has to be adjusted quickly and flexibly to the different spindle types.

New employees can use the system after a short training period.“

Examples of use

Clamping tower portfolio expanded with the “WorkBuddy” clamping aid for safe, ergonomic and efficient set-up work

WorkBuddy replaces operation by crank or torque wrench. This guarantees the shortest possible set-up times and minimum downtime.

The helper for mechanical workpiece clamping. The maximum opening or clamping speed is 10 mm/s.

A cost advantage in work preparation. At the same time, the WorkBuddy relieves the empolyees at the machine and enables ergonomic working.

Minimize shoulder weight bearing and prevent MSDs

Prevention instead of reaction

Physical stress at work – such as heavy lifting and tiresome overhead cranks – can cause musculoskeletal

disorders (MSDs).

MSDs are the most common reason that causes incapacity for work, reduced ability to work and premature

disability. They cause 22.5 percent of all AU days and €17.2 billion loss of production each year*.

The asset cost for the WorkBuddy are cheaper than the absence of only 1 employee!

*Source: Sicherheit und Gesundheit bei der Arbeit – Berichtsjahr 2017 / BAuA (Hrsg.). Numbers may vary depending on country.

Mounting at machine or set-up station

Standard modules for customization

The installation of the WorkBuddy is based on two standard support arms, which are adaptable to the

individual situation in your production. We are happy to support you with the installation!

Guiding arm (top)

Z500 R620 L1200

Art.No. 6951008000155

Guiding arm (side)

Z780 R400-600

Art.No. 6951008000255 (rechts)

Art.No. 6951008010255 (links)

Your contact

We are pleased to advise you!

Would you like to know more about the WorkBuddy?

Do not hesitate to contact us:

+49 8377 929-0

sales@allmatic.de