Short setup times, great high flexibility for machining from 5 sides

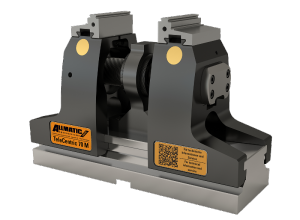

With its TeleCentric, the clamping device specialist ALLMATIC-Jakob presents a novel centric 5-axis clamping device with a standard fast attachment bracket system.

Manufacturing and processing plants require a lot of clamping system. On the one hand,

straightforward and fast handling is essential. On the other hand, machine jaws must fixate the work piece securely and with the minimum amount of vibration. Additionally, the share of 5-axis machines in production halls has been increasing significantly in the last 15 years. With its TeleCentric, the renowned clamping device manufacturer ALLMATIC-Jakob is now presenting a

secure and newly designed solution for clamping on modern 5-axis machines. Both grip clamping as well as conventional clamping are possible.

“The machine vice must not hinder the access of tools and machine spindles to the work piece”, says Herbert Mayr, managing director of ALLMATIC, about the challenge the company faced when the new product was designed. When Rösch and his colleagues designed this new range

of products, they focussed exclusively on centric clamping, hence the name “TeleCentric”. A particular highlight is the telescopic spindle, which features internal and external threads that interlock. This novel design guarantees optimum interference contours with the best possible

accessibility of the machine spindles and the workpiece. Thanks to the centric functionality, there is not zero offset and the material allowance can simply be divided in two because it is fixed symmetrically. Stating the reason for this decision of the designers by saying, the expert says, “The parallel positioning of the workpiece ensures the highest possible clamping accuracy at a maximum loading force of 30 Kilo newton and rather operator-friendly 45 Newton metres at the dynamometric key.” This is the loading force that the TeleCentric brings to the workpiece – thanks to its new lubrication-free telescopic spindle.

Another highlight is that ALLMATIC’s new TeleCentric comes with a standard attachment bracketsystem. No tools are required to adjust the clamping system swiftly to the new workpiece that needs to be machined. Thus, it’s possible to efficiently machine a sixth side by simply changing

a bracket. Of course, the team of developers did not forget larger span widths either. Their

solution? Simply turn the brackets around or provide longer ones.

The TeleCentric meets all requirements that one could have of a machine vice used in today’s 5- axis machining world. With this ALLMATIC product, it doesn’t even take ten seconds to change a pair of brackets, no need for tools, either. Workpieces are placed at a height of 192 millimetres. Even the weight of the TeleCentric is anything but usual: Depending on the model, and without the brackets, it weighs no more than 19.5 kilograms and thus makes it possible to optimize the production process, while guaranteeing great operator convenience in manufacturing plants.